This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

PIPE ISOLATIONS

Depressurizing and splitting downstream piping can be a complex and risky process. At IK Topside, we recognize the critical importance of establishing a safe and efficient workspace for our clients in the oil and gas industry. Our cutting-edge equipment for pipe isolation is designed with your needs in mind, addressing the unique challenges you face when working on piping systems. With our advanced isolation solutions, you gain the confidence to carry out these tasks safely and effectively. We provide the tools that enable you to isolate the pipe, ensuring a secure working environment for your team.

Safety First

Our equipment prioritizes your team’s safety by minimizing risks associated with working on pressurized systems, exposure to dangerous gases, and performing hot work on hydrocarbon systems.

Efficiency

Optimize your operations and reduce costs by efficiently isolating pipes. Enable your team to work on downstream piping without the need for system shutdowns or the time-consuming cleaning and gas-freeing process, saving you valuable time and resources.

Customized Solutions

We understand that every project is unique. Our team works closely with yours to provide tailored isolation solutions that meet your specific requirements.

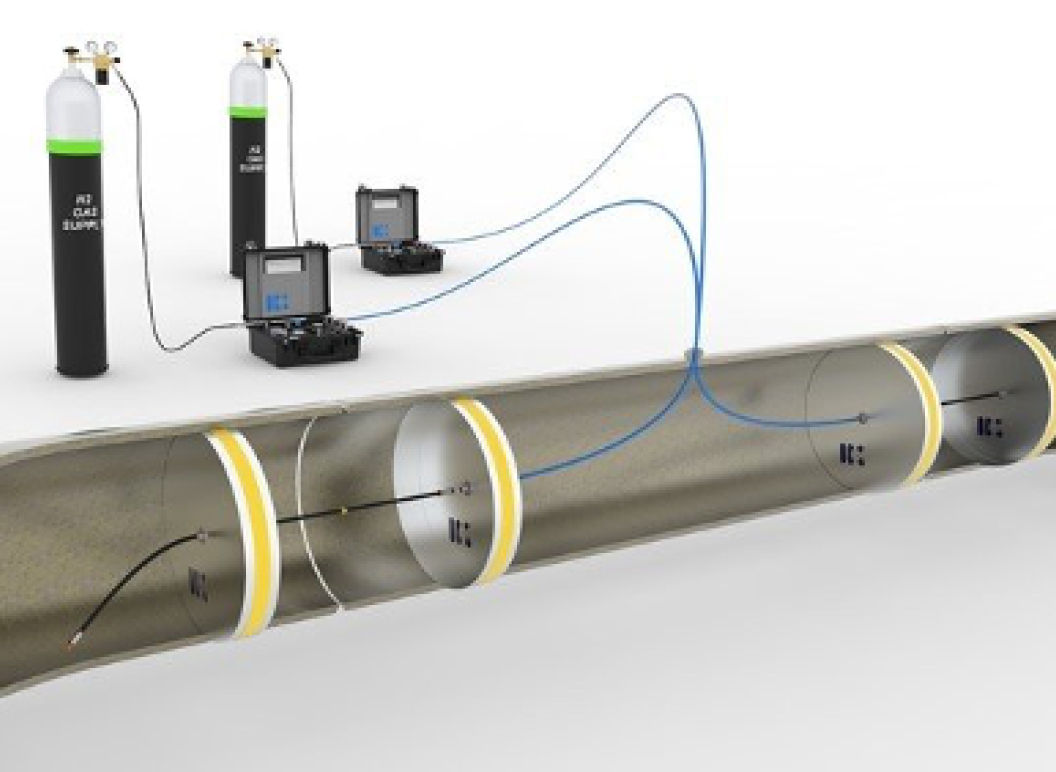

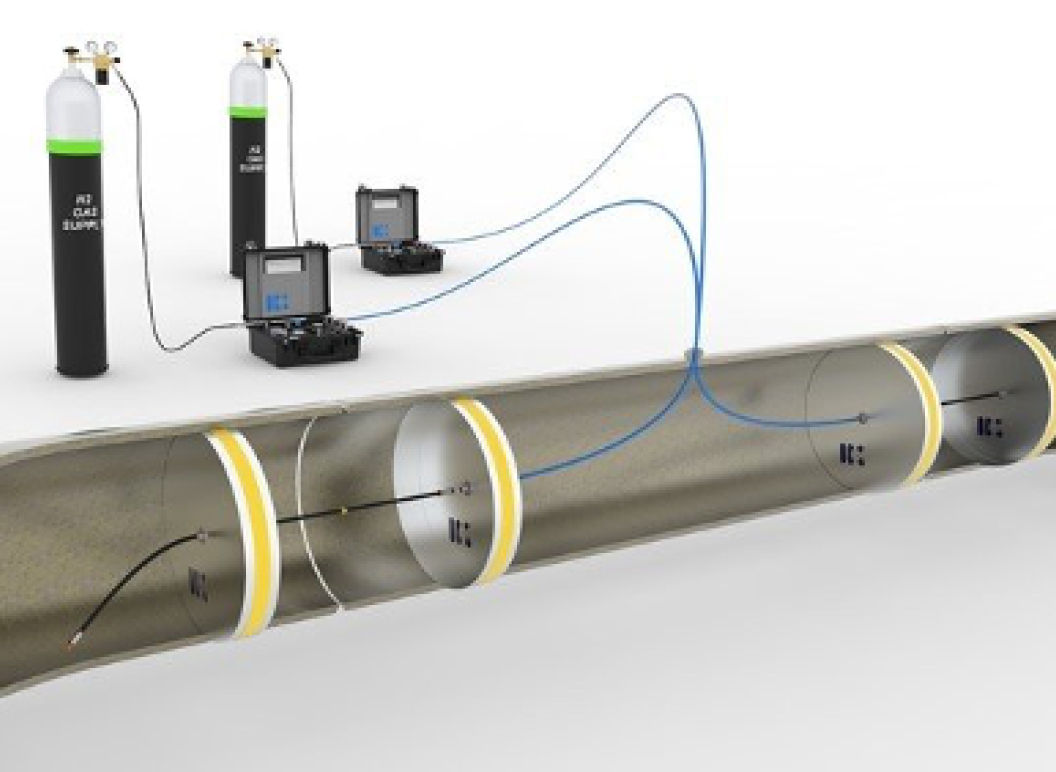

BACK-GAS

Welding intricate pipe joints often demands “golden welds”—flawless results with oxygen levels below 100 ppm. Traditional methods, such as inflatable bladders or filling entire systems, are cumbersome, expensive, and limited in application.

Time-consuming setups

Forget about filling entire pipelines or struggling with awkward bladders. We easily install our system before joining segments and retract it through a dedicated nozzle afterwards.

Wasted resources

Eliminate unnecessary gas consumption by directly targeting the weld zone.

Limited accessibility

Our system navigates complex configurations where bladders won’t reach. Weld with confidence even in tight bends and intricate layouts.

Uncertainty

Our system intelligently measures the Lower Explosive Limit (LEL) and can achieve an astonishing five ppm oxygen level, ensuring consistent, superior weld quality.

Tools Category

Back-Gas Systems:

- Valkyrie PurgePro

- Valkyrie PurgeDam

- Valkyrie PurgeShield

- Other

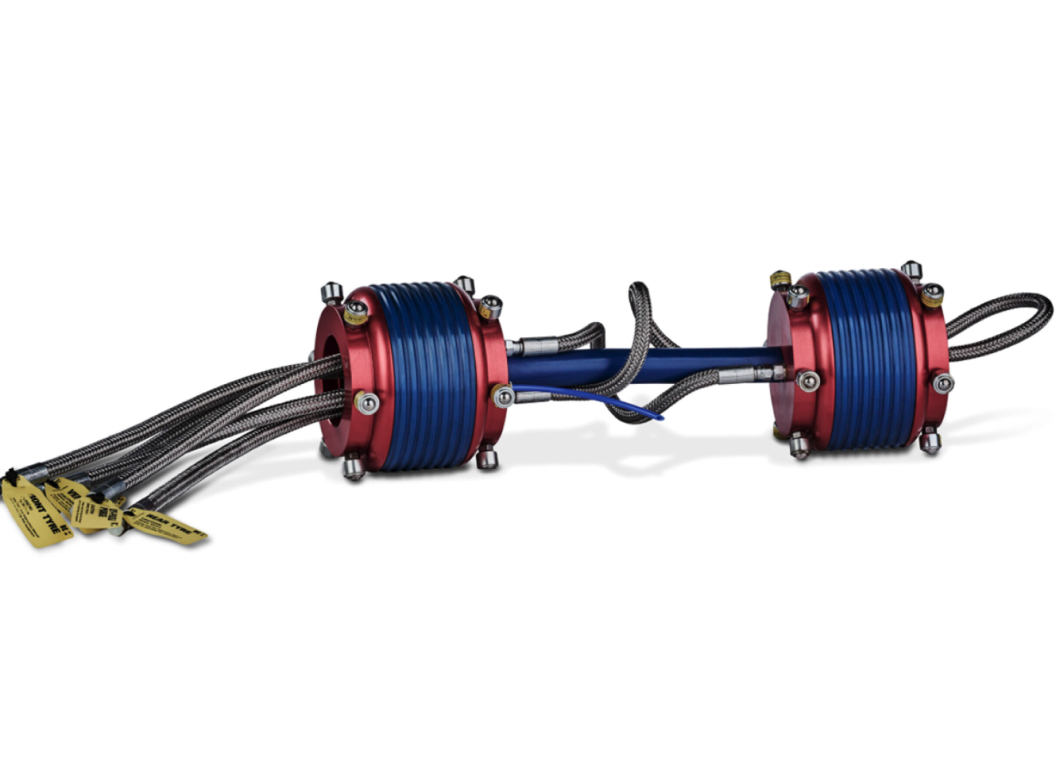

Plugging Systems:

- Composite Pipe Plug

- Compression Plug

- Cutting Pollock Plug

- Drain Plug

- Extended Plug

- Line Stopling

- Permanent Plug

- Raptor Plug

- Twin Tyre Flexible Plug (TTFP)

- Double Seal Compression Plug

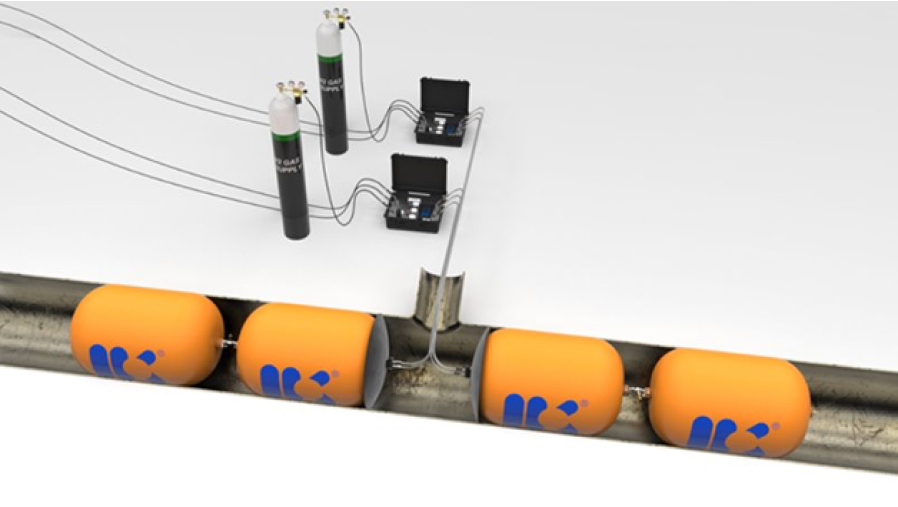

Inflatable Barrier:

- ABIS

- ABIS Hybrid

- Custom ABIS

- Mini ABIS

- VALKYRIE

- Muniball

- Peterson Plugs

- SARCO Air Bags

Ice Plugging:

- N2 Jacket

- NaCI Liquid CO2

- Pellets

Enquire now

Our friendly team would love to hear from you.