This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Specialised Weld Isolation equipment & services for Splash-Zone Riser Repair

Project description

The client, Aker Solutions (Brunei), is working on Brunei Shell Petroleum’s offshore maintenance projects. One of the client’s operational tasks involves repairing risers on offshore installations. Many risers require maintenance and repair due to corrosion, pitting and general metal loss. There are both de-pressurized risers and pressurized risers. These factors have mainly been found in and around the splash zone area. Most of these risers have miter joints around the splash zone area and are therefore not easily navigable for regular standard plugs or pigs about system maintenance or repair.

These repairs will involve replacing some sections of the risers and possibly replacing some whole riser sections/segments over sea level. This work entails cutting & welding operations. IK Topside has long experience and expertise with this type of equipment for double block and bleed (DB&B) weld isolating and cold cutting of de-pressurized risers. A DB&B barrier is essential when performing hot work operations/welding operations on these hydrocarbon process lines.

After ascertaining the required installation information through site surveys and client-supplied technical specifications and data, IK mobilized a team of specialized field engineers to supervise and perform the operations on site.

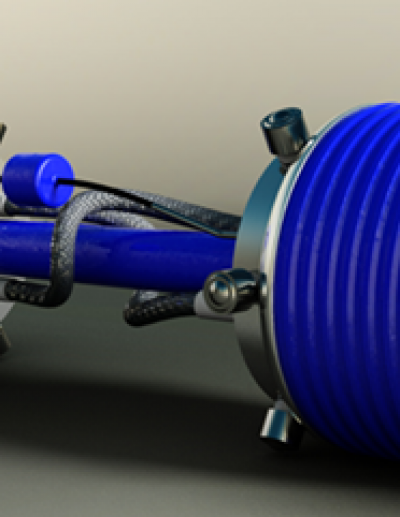

The DBB Weld Isolation Flexible Plugs are manually energized, so no electrical or pneumatic requirements are required on-site for these isolation operations. An accompanying set of hoses and lifting accessories is also available for confined areas and can replace the need for heavy lifting or crane availability.

The client can safely and efficiently perform hot-work activities using IK Topside’s specially designed flexible double barrier isolation equipment and techniques. The weld isolation equipment is locally installed, so no full pipeline cleaning or gas freeing is necessary.

“This is a perfect isolation system for this type of operation. The tools are light and flexible, and there is no requirement for heavy lifting. The equipment and operational procedures are easy to follow. Riser section changes can be performed safely, efficiently, and fully verified.”

– Peter Bjørnsen