This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Specialised Backgas Solution for New Installation Hook-up

Project description

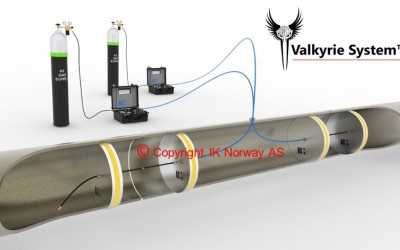

Due to the use of long, flangeless lengths of piping and multiple bends, traditional backgas equipment would be challenging to remove after welding and would, in most cases, require flushing. However, using IK Topside’s Valkyrie System™, one can avoid the traditional tasks of flushing, hydrostatic pressure testing, and drying the pipelines after the welding operations, thus significantly reducing the commissioning time and cost.

IK Topside’s Valkyrie System™ is comprised of three different back-gas system solutions to cover all pipe sizes. The solutions allow for extremely efficient welding operations due to sophisticated purge methods. All Three Valkyrie systems are removed through a 1-inch Threadolet.

IK Topside’s Valkyrie System™ products use an advanced gas purge monitoring & flow control unit. All operations are carefully planned, and all products are custom-built in-house at IK-Norway. All services are performed by experienced and certified IK Topside personnel.