This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Changeout of Drill Cuttings Discharge Hose

Project description

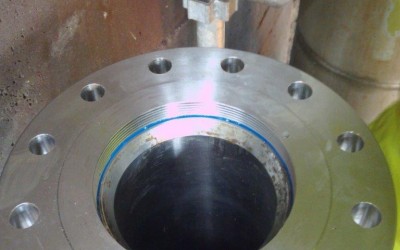

A long-standing and valued customer contacted IK Topside regarding supplying a lowering plug, holdback clamps and personnel to exchange a drill cuttings discharge hose offshore.

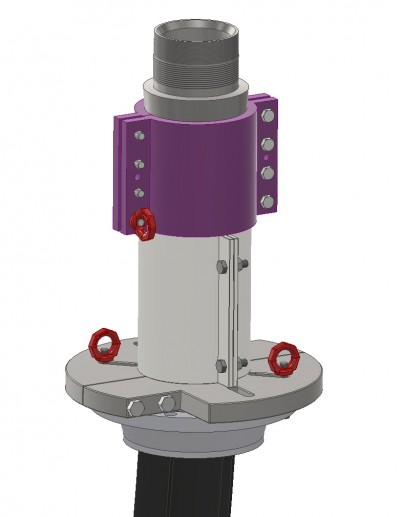

The clamp aimed to secure the old hose before unscrewing the flange and lowering it to the seabed. Also, a separate clamp was needed to secure the new hose after being pulled in and fitted with a flange for permanent installation.

The lifting plug was designed to fit inside 6 in crimp fitting for lowering the old hose to the seabed. The tasks included engineering, calculation, manufacturing, and proof testing. Thanks to the operational procedure during the mobilisation and preparations offshore, a deviation from the originally supplied dimensions was discovered.

The clamp was sent back to IK-Topside for re-engineering and modifications, and the need for a lowering cap was discovered. Within 24 hours of receiving the clamp, the team engineered, calculated, modified, and manufactured the clamp and lowering cap. The delivery was back on the harbour for mobilisation before the support vessel was ready to leave for offshore installation.

“I am incredibly proud of the team’s ability to deliver good quality safely and within a short amount of time. By supplying our service at such a high level, the customer saved in the ballpark of 1.5M each day by not having the support vessel on standby for the offshore operation. Best of all, the client was satisfied and impressed by the performance, quoting, “IK Topside should change our name to FLASH Engineering.”

– Tormod Sekse Bilstad